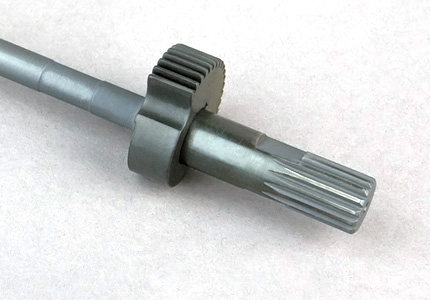

Lee’s Enterprise is proud to announce the acquisition, installation, and full qualification of a new 2014 Studer FAVORIT CNC ID/OD Grinder. The machine was acquired to increase grinding capacity to meet current and future customer demand.

Category Archives: Performance Optimization

Performance Optimization and Alternative Energy

Lee’s has evaluated performance and optimized as it relates to their entire enterprise. This analysis has led to the development of many non-traditional opportunities for performance optimization and improvement.

Lee’s has evaluated performance and optimized as it relates to their entire enterprise. This analysis has led to the development of many non-traditional opportunities for performance optimization and improvement.

As a Purpose Driven Organization we decided to explore how we could make a major positive impact, not only on the environment, but also on the cost or products and services to our customers. These are win/win solutions.

One of our major solutions for 2014 is to transfer our energy strategy from traditional generation to solar. Solar will generate 40% of our energy needs into the future and will reduce our energy costs substantially. This will impact both product cost and our carbon footprint.

This is just one more way that Lee’s is taking responsibility for the future and that of our society in general.

Performance Optimization and QLI

What is QLI? It stands for Quality Leading Indicators. This is a system introduced to us by Eaton, a major customer. They use it to manage their company. Because of our prior performance they had selected us to help them to develop a template and methods for implementing this management system among their supply chain.

What is QLI? It stands for Quality Leading Indicators. This is a system introduced to us by Eaton, a major customer. They use it to manage their company. Because of our prior performance they had selected us to help them to develop a template and methods for implementing this management system among their supply chain.

Unlike other management systems, and continual improvement approaches, it incorporates predicative analytics. These are leading indicators that help us to understand in advance the health of our business systems and processes.

In this way it is not reactive, but rather predictive, so we can act before anything bad occurs. It allows us to better see our future and make decisions today to overcome future risk. This will help us to optimize our performance and consistency going into 2014.

We are in the process of developing our model for this system and will have it fully implemented by the end of the first quarter.

Performance Optimization and Engineering

Early last year we evaluated the key elements that we thought had led to our success with On Time Delivery and Quality. One of these was in the inclusion of engineering expertise at the quote stage of our manufacturing process.

Early last year we evaluated the key elements that we thought had led to our success with On Time Delivery and Quality. One of these was in the inclusion of engineering expertise at the quote stage of our manufacturing process.

We work in a team, with both engineering and quality, to develop quotes that incorporated best practices into the process from engineering and quality. From this evaluation we decided to enhance our engineering department and invested in a new manager to add both capacity and further expertise to this strategic advantage of our firm.

This new team member is helping us to work even better with quality and production to ‘do it right the first time’. This was an investment made to help us to achieve our overall objective of performance optimization.

Performance Optimization and AS9100

Our version of AS9100 is what we have called ‘ AS9100+’. We see three levels of implementation of AS9100 used throughout the aerospace community. The first level is compliance only. In this case the firm is doing what they need to do to comply but have not bought into, or accepted AS9100, as the quality approach for their organization.

Our version of AS9100 is what we have called ‘ AS9100+’. We see three levels of implementation of AS9100 used throughout the aerospace community. The first level is compliance only. In this case the firm is doing what they need to do to comply but have not bought into, or accepted AS9100, as the quality approach for their organization.

The second level is compliance and use. These firms not only comply but also do their best to actually use the system to run and mange their quality processes. Beyond this are organizations such as ours that not only have embraced the AS9100 System, and implemented it, but also having it under continual improvement (CI).

The CI process for us is our Performance Optimization Plan where we look for new opportunities to add to the AS9100 System to help us to outperform the competition. We create new ideas that while keeping the philosophy of the AS9100 System, push us to new levels of performance.